PRODUCT OVERVIEW

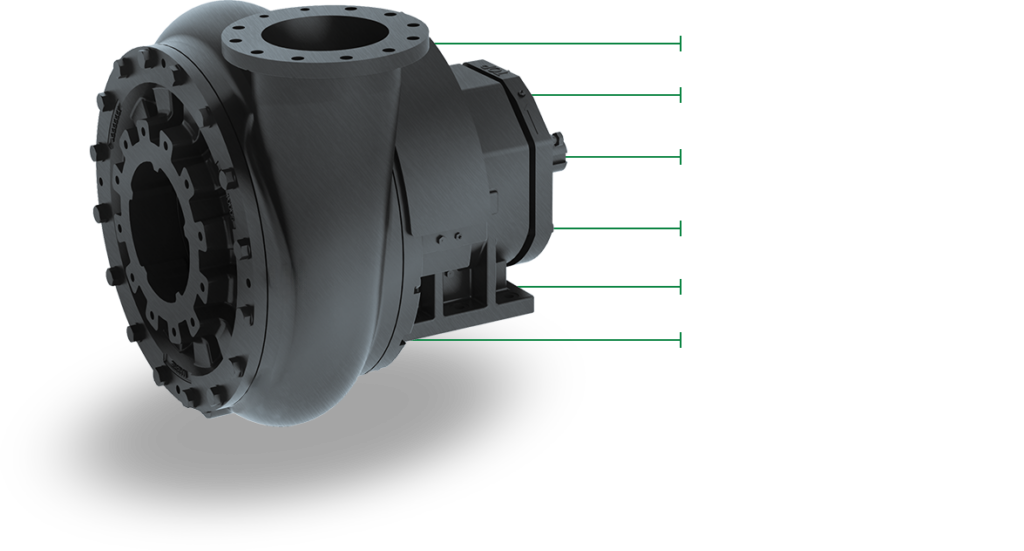

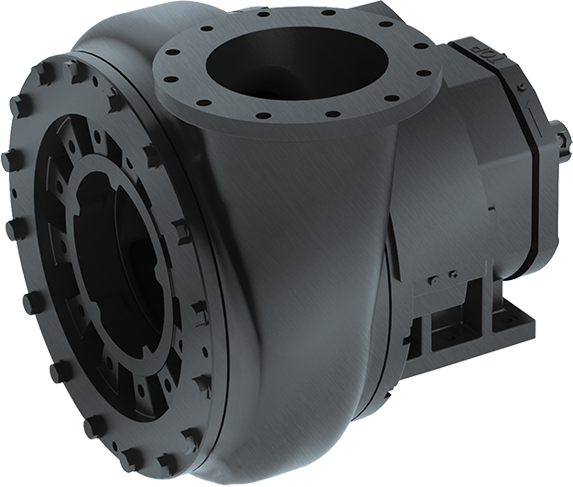

Silverback Blender Discharge Pump

Meet Silverback. Its unique design eliminates the need for mechanical seals or packing: which is the leading cause of pump failure. The result is a leak-free pump that refuses to quit. Silverback lasts up to 40 times longer than legacy pumps – offering the lowest total lifetime cost of ownership. Suddenly, you’ll view pumps as a capital investment versus a troublesome disposable commodity.

Advantages

Experience the Immediate IMPACT to Frac Operations

Silverback dominates the landscape in the highly competitive North American fracking industry where failure and unscheduled downtime are the enemy of productivity and profit margins.

Built Stronger. Lasts Longer.

Most operators go through 2 to 3 pumps in a single frac.

Silverback Pumps last for up to 20 fracs before needing reconditioning.

No-Seal. No Leak Design.

Silverback’s ingenious design eliminates mechanical seals – to radically extend product life, reduce maintenance, and eliminate leaks.

Get More Out of Your Pumps – and Your Margins.

Dramatically reduce non-productive time and pump replacements by eliminating unplanned and critical pump failures.

Built to Solve Challenges.

Cavitation | Excessive Erosion | Fluid Leakage | Impeller or Flange Wash Outs | Bearing Cartridge Failures | Premature & Catastrophic Failures

FEATURES & BENEFITS

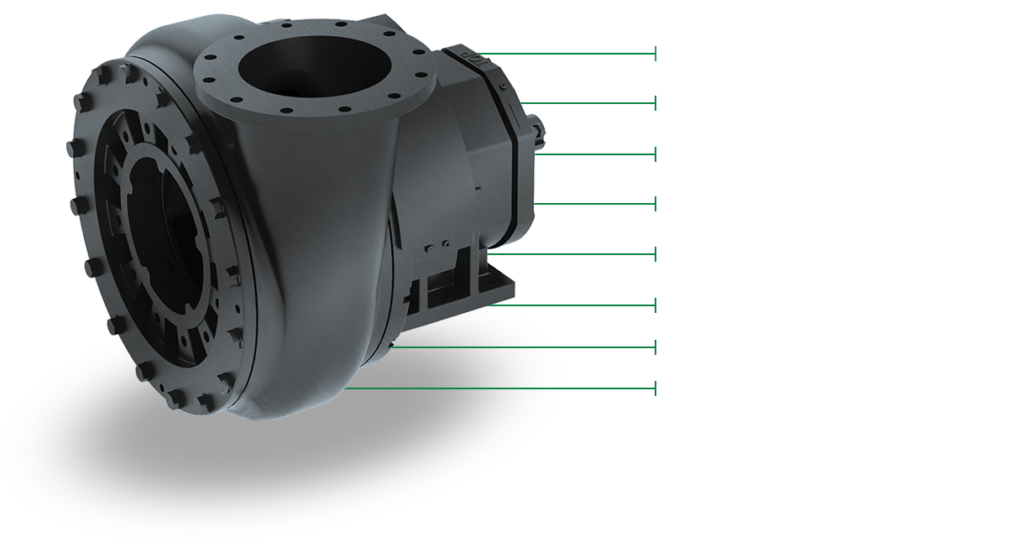

Brute Strength. Ingenious Design. Dominant Performance.

Features

- High-pressure pump-out vanes to increase wear resistance

- Run at a constant speed of 1,000 rpm to dramatically reduce wear

- Heavy wall construction eliminates flange washouts and cracked pump cases

- Heavy-duty bearing housings and wear plates (full slurry pump)

- No mechanical seals or packing, high-quality lip seals and expeller

- Virtually eliminates ‘automated shutoff’ delays due to leakage

- Fully dry run capable

- Drop-in replacement for industry standard 12x14x22 pump

- Keeps crews working and operations flowing

- Virtually eliminates any risk of pump-related leaks

- Proven to pump up to 1 billion pounds before a wear-related rebuild is required

- Delivers approximately 5.5 million pump strokes with 1000 hours of uptime

- Maximize efficiency throughout product lifecycle

- Reliable and repeatable performance, even as the pump wears

Models

Four Fit-for-Purpose Designs

Standard

Slurry

14x12x22

Silverback was designed and developed to be a drop-in replacement for your existing discharge pump, so the upgrade is easy. Our standard slurry pump offers the performance of a 14X12 at 20% lower speed in the same footprint, drastically increasing reliability and uptime. This pump lasts up to 40 times longer than other OEM comparable pumps – offering the lowest total cost of ownership on the market.

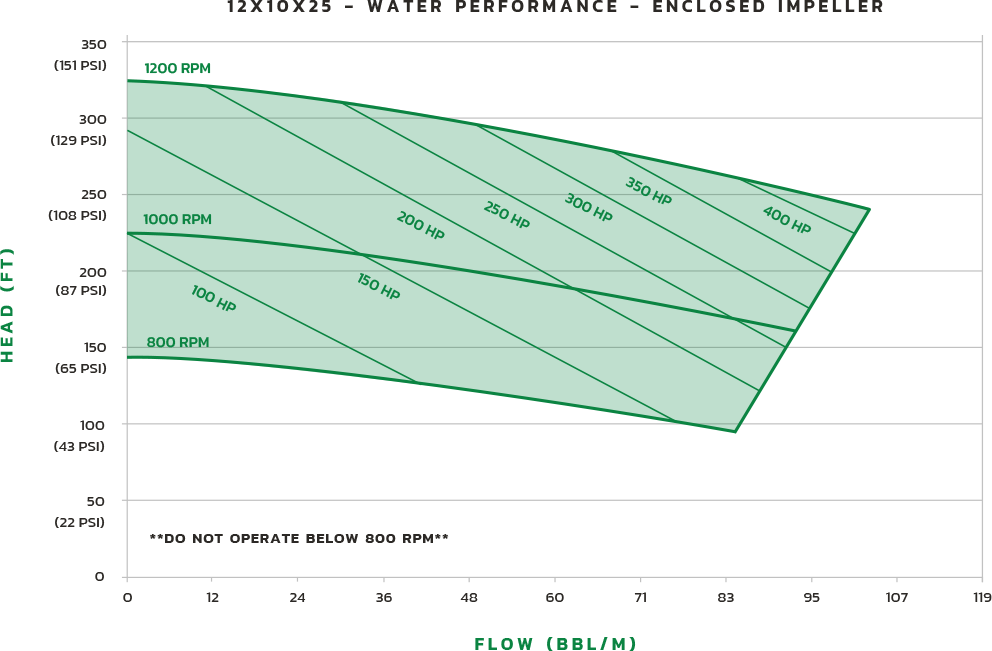

Low-Flow 12x10x25

Maximize efficiency throughout your frac operations. The Silverback Low-Flow Blender Discharge Pump is designed for applications that require lower proppant volumes and demand a smaller footprint.

Semi-Open High Proppant Rate 14x12x22

Elevate your frac operations with the Semi-Open High Proppant Rate Blender Discharge Pump, tailored exclusively for the dynamic demands of the industry. Engineered to excel, this pump is designed to enhance the reliability of your frac blender. Its innovative semi-open design empowers efficient handling of high proppant volumes, optimizing flow.

Top

Drive

The Silverback Overhung Top Drives are designed and developed to improve frac blender reliability. The chute is strategically designed to handle more proppant volume. The closed loop lubrication system with pump, filter, cooler and overpressure protection ensures long operation without requiring overhaul. Our improved bearing and seal design mitigates bearing failures and allows higher oil pressure circulation for better performance and increased uptime.

Resources

Specifications & Brochures